Great Down belongs in Great Fabric

The outer layer of a duvet is the fabric cover which encases the down or feather filling. Cotton is the best material for this as it can be woven in such a way as to keep down and feathers from escaping while simultaneously promoting ventilation and preventing dust from entering. Quality duvets generally use 100% cotton covers.

The quality of fabric effects a duvet’s insulating power, durability, and softness. As such, it is important to understand what fabric is used, the different ways it can be woven, and how we measure its quality in order for you to determine the best duvet for you. Continue reading to learn more about how our duvet covers are made and how they impact your sleep experience.

Ne Value

The quality of cotton is indicated by its cotton count or Ne value (Ne refers specifically to the English unit of measurement for the cotton count). An Ne value of 1 means that there are 840 yards of yarn in every pound; as the Ne value increases, the number of yards per pound of yarn increases proportionally. A high Ne value corresponds to a strong and tight fabric. Ne 30 is the minimum quality for down duvets. At Downduvet.co.uk, we only offer duvets with fabric of Ne 60 or higher. Recently there has been an increase in Ne values at the upper end of the market, with duvets being made with values of up to Ne 155.

A duvet with a higher Ne value drapes better over your body, reducing the spaces between your body and the duvet. A duvet with a lower Ne value is more rigid and therefore does not fall so snugly around the body, creating more pockets of air around you which force the body to produce more heat.

German Terms, English Measurements

Below is a conversion table demonstrating the equivalence of English and German terms for different kinds of fabric and their respective Ne values.

| English | German | Ne Value |

|---|---|---|

| Mako cambric | Einschütte | 60 |

| Down batiste | Daunenbatist | 80 |

| Fine down batiste | Feinbatist | 90 |

| Noble down batiste | Edelbatist | 100 |

| Premium batiste | Feiner Mako-Batist | 120 |

| Superior batiste | Feinster Mako-Batist | 150 |

Varieties of Woven Fabric

There are several methods of weaving cotton into duvet covers. These methods can affect a duvet’s overall weight, feel, warmth, and ventilation.

Cambric

Cambric fabrics are woven from Ne 40 thread in the traditional linen binding method seen below. The weft alternates over and under the warp thread and the second weft goes in the opposite direction to the first. For generations, Cambric fabrics were the standard covers for German down duvets.

Traditional linen binding

Traditional linen binding

Batiste

Our batiste fabrics are woven from thread of Ne 60 to Ne 160, also in the traditional linen binding method shown above. Because of the nature of the weave, cambrics and batistes look and feel the same from both sides.

Traditional satin woven fabric

Traditional satin woven fabric

Satin Woven

Satin woven fabric is distinct from cambric and batiste in that the weft goes alternately over several threads and under one warp thread. Satin woven fabric is very supple, soft, and it stands out because of its smooth gloss. From one side, the weft is visible and from the other the warp is visible.

Sewn Through or Baffle Box?

Some duvets have a square pattern, formed by the criss-crossing lines where the upper and lower parts of the fabric have been directly stitched together. This technique, called “sewn through”, is generally used for lighter, more summery duvets. Watch the video below to see how one such duvet is made.

Warmer duvets are made up of boxes. In such duvets, the upper and lower parts are not directly sewn together. Instead, vertical inner walls of fabric are incorporated into the duvet, separating the two sides of the and creating box compartments to be filled with down. This “baffle box” technique was developed to ensure cold air couldn’t seep in through the stitching of a duvet. For this reason, it is mainly used in winter duvets.

Depending on the thickness of the duvet, the inner walls of a baffle box can be between 2 and 10cm in height. The thickest baffle box winter duvets, with walls of up to 10cm, are called “Hochsteg” (high baffle) and will keep you warm even on the coldest nights.

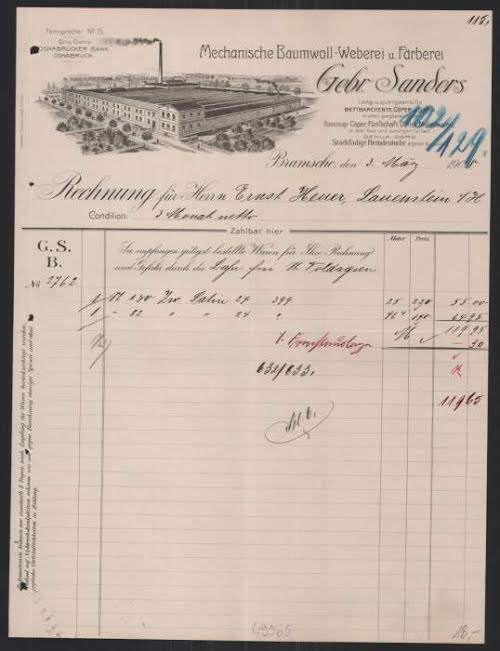

Fabric Manufacturers

German and Austrian manufacturers are renowned for the exceptional quality of their fabric. Much of the fabric found in our duvets is made by companies with extensive histories, and the weight of all this experience is immediately apparent in the superior quality and feel of their covers. Sanders (Germany), Weidmann (Germany) and Hefel (Austria) are some of the prestigious manufacturers whose fabric can be found in our duvets.

For over 300 years the city of Bramsche in Germany has been synonymous with densely woven fabrics known as ‘Bramscher Tuch.’ Since 1885, the head office of Sanders has been located in Bramsche.

For over 300 years the city of Bramsche in Germany has been synonymous with densely woven fabrics known as ‘Bramscher Tuch.’ Since 1885, the head office of Sanders has been located in Bramsche.

Down Duvet Buying Guide

Choose your perfect down duvet in 4 simple steps.

- Duvet Size: Which size do I need?

- Tog Rating: Pick the right tog

- Fill Power: Understanding fill power

- Duvet Fabric: Quality fabric for comfort

Compare all down duvets by price, size, season, brand, fill power, fabric, and down type.

Have questions? We’re here to help!

020 3129 5731 (working days 9am – 4pm, GMT)