Quality Control of Down in 6 Steps

Each duvet workshop featured on Downduvet.co.uk uses extensive quality control measures to ensure product quality and reliability. A sample is taken from every shipment of down as it arrives and tested for quality. Each time the down is washed, a new sample is tested. Testing ensures that the down is pure and free from foreign bodies, and determines its oxygen content and elasticity. Only when enough samples have been thoroughly and scientifically tested is a shipment of down released for further processing.

Inspecting the down after the final wash

Inspecting the down after the final wash

Quality Control of Down in 6 Steps

1) Determining Species

The first step in analysing down quality is figuring out what animal the down comes from. With the aid of a magnifying glass, a trained eye can quickly discern whether a piece of down came from a duck or a goose. Tiny barbs on the hair differ in size and position depending on the species (goose barbs for instance, are a bit larger and are found in the middle rather than at the end of the hairs).

2) Finding the Proportion of Suitable Down

After the species of origin is identified and confirmed, the ratio of quality down to down which has been broken during transport is calculated from a sample. Three grams are tested to ascertain the percentage of usable down.

Down and feathers inspected in laboratory

Down and feathers inspected in laboratory

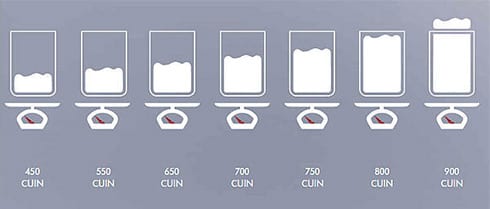

3) Calculating the Fill Power

Calculating the fill power of each shipment of down is essential to ensure that customers get the quality down they are paying for. Quality is measured in mm / 30g or in CUIN. Fill power indicates down’s ability to return to its original form after being compressed. The better the down is at decompressing, the warmer it will be. This is tested scientifically using a Lorch cylinder. You can find out more about fill power and how it is measured on our fill power page.

Fill power in cuin table

Fill power in cuin table

4) Determining Purity

Following this, the purity or transparency of the down is assessed. After each washing, the used water is poured into a cylinder with a black cross at the bottom. If this cross is still visible after filling the cylinder with 30cm of liquid, the down is considered sufficiently washed and thus ‘pure’. If the down does not qualify as ‘pure’ it is washed again.

Each workshop has its own quality standards. Kauffmann, for example, only uses down with a cross visible at a height of 80 cm.

5) Measuring Oxygen Content

After the down is found to be clean and transparent, the oxygen content is measured using 100 grams of test material. With the oxygen test, if there are any harmful substances that cannot be detected with the naked eye, they are identified and removed.

Measuring cylinder with liquid

Measuring cylinder with liquid

6) Calculating Residual Fat Content

Last but certainly not least, the residual fat content is measured. Down with too low residual fat content (less than 0.7%) is fragile and will not last long. Conversely, if the residual fat content is too high (more than 2%), the down might develop unpleasant odours. Only down within this ideal range is subsequently used in duvets.